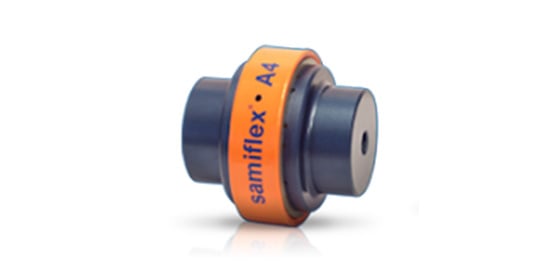

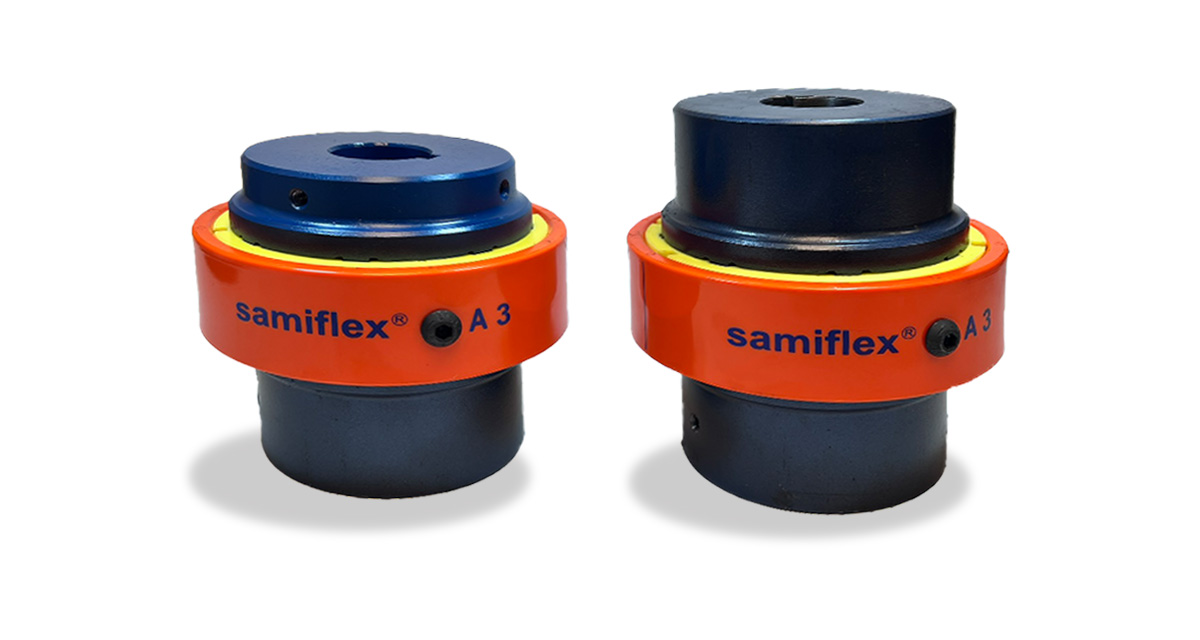

SAMIFLEX - ELASTIC STYLE COUPLINGS

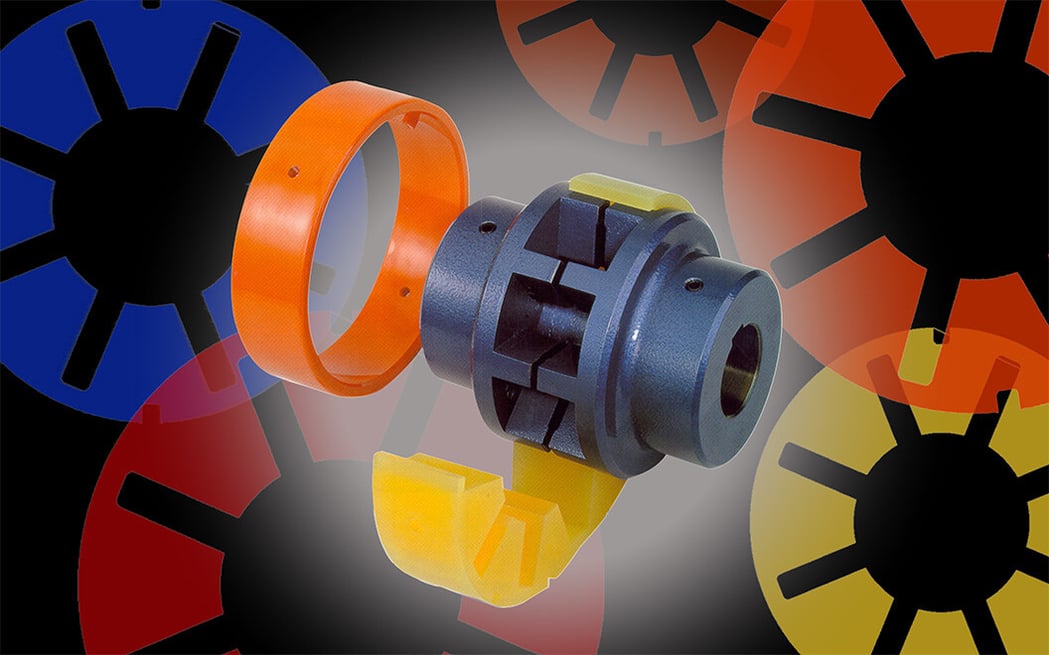

SAMIFLEX Couplings and Inserts

A nearly maintenance-free solution that reduces expensive downtime.

Samiflex couplings are designed for easy inspection and quick insert replacement. Inserts can be replaced in minutes, not hours - with no need to ever move the driving or driven equipment or add any lubrication.

Installation - As Easy as One, Two, and Three.

-

Align both of the hubs (A) and (B) on the shafts.

-

Insert the elastic insert (C) into the parallel slots between hubs (A & B).

-

Slide a polyamide or steel retaining ring (D) over the insert, securing the insert and ring between the hubs.

Once hubs A and B are installed and aligned, you can easily replace the insert at any time—there’s no need to reposition the hubs. Simply slide the retaining ring (D) to remove and replace the insert, with no special tools required.

.png?width=309&height=250&name=images%20(no%20background).png)

Strategic Operational Advantages

- Massive Time Savings: Inserts are replaced in minutes, drastically reducing maintenance labor time.

- Near-zero Maintenance: No lubrication is ever required, eliminating messy grease schedules and associated material costs.

- Motor testing simplified: Hubs can be rotated independently.

- Large bore to torque capacity: Accommodates larger shafts for a given torque, allowing you to choose a smaller coupling size without sacrificing performance. This results in lower costs and reduces rotational inertia for improved efficiency.

- No metal-to-metal contact: Eliminates wear mechanisms (fretting, abrasion), corrosion between hubs. Extends machinery life by reducing operational stresses. No risk of sparking.

- ATEX safety standard for use in hazardous environments: Samiflex couplings meet the ATEX requirements for group II (explosive environments), category 2G (gas) and 2D (dust), explosion group IIC, and temperature T4.

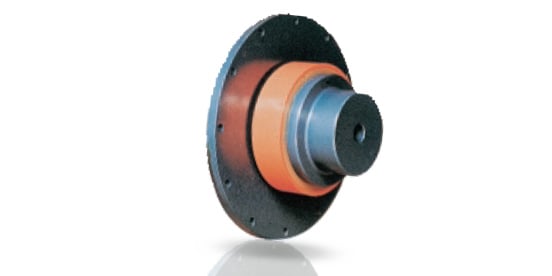

- Coupling Orientation: The standard coupling design is fully suitable for both horizontal and vertical installations without requiring special modifications or tools.

- Retaining rings: Retaining rings are available in polyurethane or steel and come with locking screws as standard.

Samiflex Elastomeric Inserts

Samiflex inserts are manufactured using specialized polyurethane compounds. Inserts are available in three compounds and three hardness ratings, allowing us to precisely match the coupling’s torsional stiffness and chemical resistance to your specific application and environment.

Our material formulation for the orange, high-temp (HT) insert, provides reliable performance across extreme temperature ranges from -40°F to 300°F.

Standard (STD) yellow elastomeric inserts will be supplied with coupling orders unless otherwise specified.

Contact us for assistance with sizing and selection.

Samiflex Insert Advantages

- Exceptional Quality: Inserts are manufactured from premium materials to deliver exceptional tensile strength and minimize breakage or shearing.

- Designed for demanding environments: They offer outstanding resistance to humidity, oils, corrosive vapors, and a broad range of chemicals. Proven longevity and durability in abrasive slurries.

- Superior shock and vibration damping: The material effectively absorbs and isolates shock and vibration from machinery, helping to protect system components by preventing harmful forces from traveling through the shaft and damaging them.

- Misalignment protection: The insert compensates for all forms of simultaneous misalignment (radial, angular, and axial). This constant flexibility is crucial for extending the operational life of expensive components like bearing assemblies and mechanical seals on your driving and driven components.

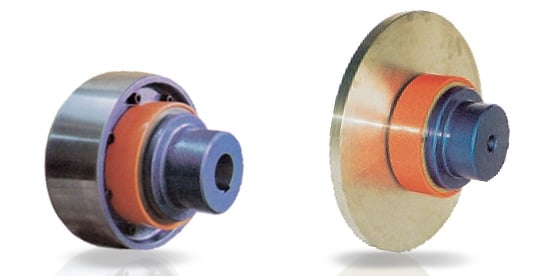

CDWdrives modifies and customizes assemblies to meet your exact application specifications.

Our service and repair shop

Fast modifications and custom assemblies

Samiflex couplings from CDWdrives are delivered fully assembled with custom bore and keyway sizes to match your equipment. Each coupling includes a setscrew to securely lock the ring in place. Our shop can quickly modify hubs to your specifications and build custom assemblies to fit your application.

Standard Type A Coupling Technical Details and Dimensions

Contact CDWdrives for Specification and Tech./Dimension sheets on other coupling types

SAMiGUARD

The SAMiGUARD is a new overload protection system.

SAMiGuard is designed to address the drawbacks of conventional shear pins. It uses a tapered pin (fuse) to overcome issues such as pin fatigue, fretting, and uncertainty in load sharing. This innovative system aims to enhance safety and minimize downtime in process plants.

Key Advantages:

- Fast maintenance—reset the drive in minutes by simply replacing the fuse

- Tapered design ensures maximum rigidity and eliminates wear from backlash

- Clamping screws maintain precise axial alignment; shear neck remains securely positioned between flanges

- Consistent load distribution with multiple fuses for high-torque applications

High torque capacity in a compact footprint - Standardized, color-coded shear necks for safe, tamper proof - reliable operation and simplified spare parts management

- Fail-safe performance in any environment—unaffected by temperature or humidity changes

- Reliable release function that does not require lubrication