2 min read

Samiflex Couplings and Inserts Protect Your Equipment from Costly Downtime

Diann Sobolewski Sobolewski : Nov 9, 2021 1:35:00 PM

Introducing a Cost-effective Solution for Coupling Failure

Say goodbye to costly and troublesome coupling failure issues with our new maintenance-free Samiflex elastomeric couplings and inserts. Samiflex Couplings reduces premature failure and is highly cost-effective, minimizing expensive downtime.

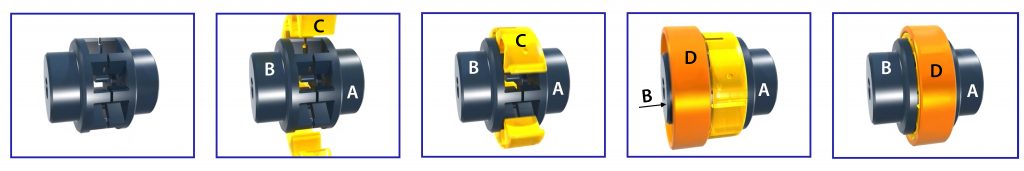

A Samiflex Coupling has only four parts: two cast iron or steel hubs, one precision cast polyurethane insert, and one retaining ring made from either polyamide or steel. Assembly is simple and requires no nuts and bolts or special tools.

Assembly and Disassembly

Align hubs (A) and (B) on the shafts. Insert the elastic insert (C) into the parallel slots between hubs (A & B). Slide a polyamide or steel retaining ring (item D) over the insert, securing the insert and ring between the hubs. Retaining rings are provided with locking screws as standard.

Once the hubs (A) and (B) have been installed and aligned on the shafts, the coupling hubs will not have to be moved again during the life of the equipment. The insert is quickly and easily removed and replaced without the need to undo screws, bolts, or other fasteners by simply removing the retaining ring (D).

You can watch," the video to see how easy it is to replace a Samiflex insert.

Advantages

- Easy installation: Replacing a Samiflex elastic coupling is more straightforward and faster than changing out any other type of coupling. The axially split coupling insert design allows for the removal and replacement of inserts without the need to move either driving or driven equipment. You don't need any special tools.

- Maintenance-free: No lubrication is required over the life of the insert.

- Inspection and service made easy: Because you can rotate the hubs independently, you can inspect the direction of rotation before completing the assembly. The coupling hubs do not mesh together, causing metal-to-metal contact and excessive wear. Inspection and replacement of a Samiflex coupling inert can completed in seconds by moving the retaining ring to one side to access, view, and replace the insert. Another advantage of using a Samiflex coupling is that the driven machine is isolated, making removal of the insert very easy for inspection and maintenance.

- Long-lasting: On average, inserts last 25,000 working hours (3 years). Inserts have a longer operational life and an indefinite shelf life because they are not affected by UV light and do not degrade like rubber inserts.

- Durable: The inserts are individually cast from a unique blend of baked and cured polyurethane. This process ensures the insert's integrity is not compromised and the performance remains high. Polyurethane inserts are very resistant to corrosive and chemical attacks.

- Small to large torque: Applications from double digits up to 200,000 Nm of torque are available with shaft dimensions ranging from Ø8mm to Ø300 mm. Polyurethane insert hardness options are available to optimize torque capacity and damping.

- Versatile: The standard coupling allows for both horizontal and vertical operations. An SAE flywheel and custom mounting arrangements are also available.

- Inserts available for every application and environment: Selecting the appropriate insert type for your application will significantly increase its performance. Samiflex manufactures inserts from a unique blend of polyurethane. They are available in three styles of compounds and three hardness ratings, allowing you to select inserts that meet or exceed your application needs. Different Polyurethane insert harnesses are available to optimize torque capacity and damping. The standard insert can handle an extensive temperature range from -40 to 80°C (-40 to 180°F). High-temperature inserts are available up to 150°C (300°F).

Samiflex Elastomeric Insert

Unless specified, we typically supply the standard (Yellow) elastic insert at 95 shore A. High-performance inserts type HD (red) and HDT (brown) increase torque ratings by 40%. High-temperature (orange) inserts have a temperature rating of -40/300 °F.

CDWdrives is the North American distributor for Samiflex products. Please get in touch with us today for help in proper sizing and selection.