- Home

- LHD Load Handling Devices

- LHD Unit Transfer Systems

LHD Unit Transfer Systems

CDWdrives (LHD-USA) is the North American Distributor of LHD Products. LHD Group designs and manufactures Special Load Handling Devices like Unit Transfer Systems

Our load-handling devices and systems are used in automatic warehouses, pallet handling, and mini-loads.

APOLLO

APOLLO—Load capacity up to 1500 Kg (3307 Lbs). The APOLLO system incorporates telescopic forks and a conveyor, enabling separate pallet handling. The conveyor can lift while the fork is closed, reducing cycle times in an automated warehouse. This system allows the conveyor to place the load in the unloading bay without employing the forks. Additionally, the APOLLO system can improve the position of the load on the shelf by aligning it with the forks, ensuring that the load is always set down in the same position.

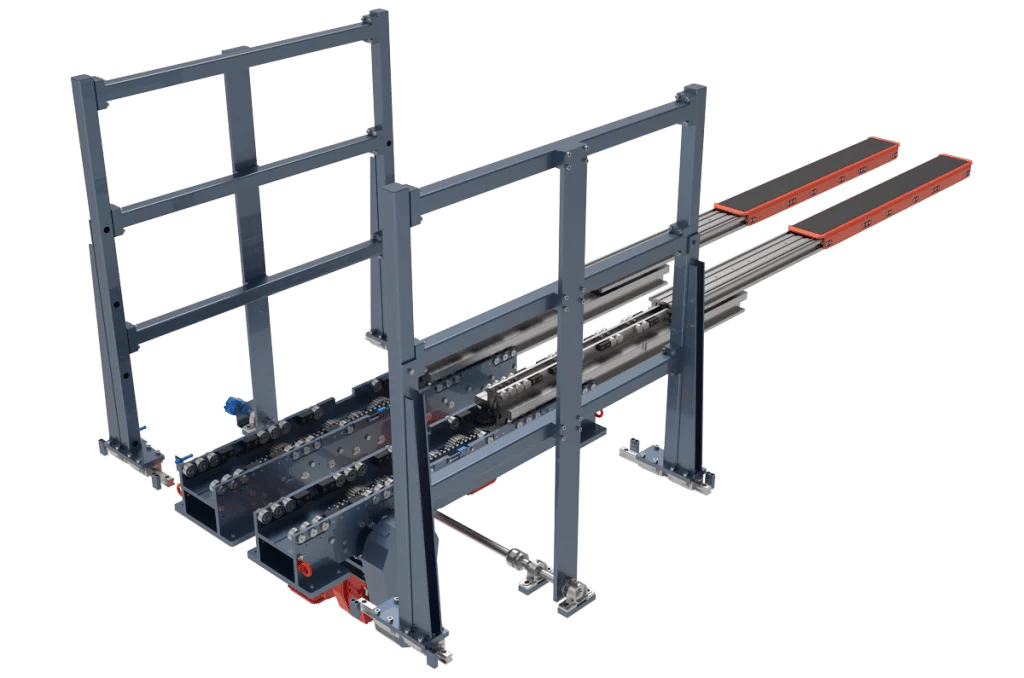

CERBERUS X1 for Pallet Handling

CERBERUS X1 – Load capacity up to 1500 Kg (3307 Lbs). The CERBERUS has 42 mm thickness fixed forks with a rotation and translation speed as fast as 30 m/min. This system picks up and sets down pallets and can rotate them 90 degrees from their original position. The CERBERUS X1 is operated through a racks and pinions style transmission. This fork is ideally designed for pallet handling; a motor placed on top operates the spinning movement, and the whole structure is supported by a system of prismatic rails, the size of which depends on the weight of the equipment. Both rotation and translation movements can co-occur.

CERBERUS X2 for Coil Handling

CERBERUS X2 -Load capacity up to 1500 Kg (3307 Lbs). LHD designed the CERBERUS X2 (3-sided system) for handling metal or paper coils. The rotation and translation speed can be as fast as 30 m/min. This system's innovative design allows coils to be easily picked up, set down and even rotated 180 degrees from their original position in the warehouses. The CERBERUS X2 is operated through a racks-and-pinions-style transmission.

CERBERUS X3 STINGER

CERBERUS X3 - Load capacity up to 2500 Kg (5512 Lbs). The CERBERUS Stinger with a central pipe design is a similar solution to CERBERUS X2 for Coils. The rotation and translation speed can be as fast as 30 m/min. This system allows the coils to be set down and picked up, even rotated 180 degrees from their original position in the warehouses.

CERBERUS X4 STINGER

CERBERUS X4 – Load capacity up to 2150 Kg (4740 Lbs). Cerberus X4 with the central pipe is a similar solution as CERBERUS X2 for COILS. The rotation and translation speed can be as fast as 30 m/min. This system allows the COILS to be set down and picked up, even rotated by 360 degrees compared to their normal position in the warehouses.

GRYPHON

The GRYPHON operates in conjuction with telescopic forks (usually monoforks) for miniload handling. It helps to keep load units stable and aligned during movement, particularly for light but voluminous carton boxes, preventing misalignments on the shelves that could result in collisions.

GRYPHON

HERMES—Load capacity up to 300 Kg per unit (662 Lbs). The HERMES, operating jointly with telescopic forks for special loads, allows the operator to cherry-pick the desired items from multiple storage units. An onboard selection system lifts the items for selection while the telescopic forks put back down the remaining units. Also available for miniload boxes.

MEDUSA

MEDUSA – Load capacity up to 100 Kg (220 Lbs). The MEDUSA is a double-depth telescopic fork (usually in a monofork arrangement) with an extending plate that can shift along the upper slide when the forks are in the center position. This movement allows the load unit to be repositioned on the upper slide according to the customer's needs without needing side belts.

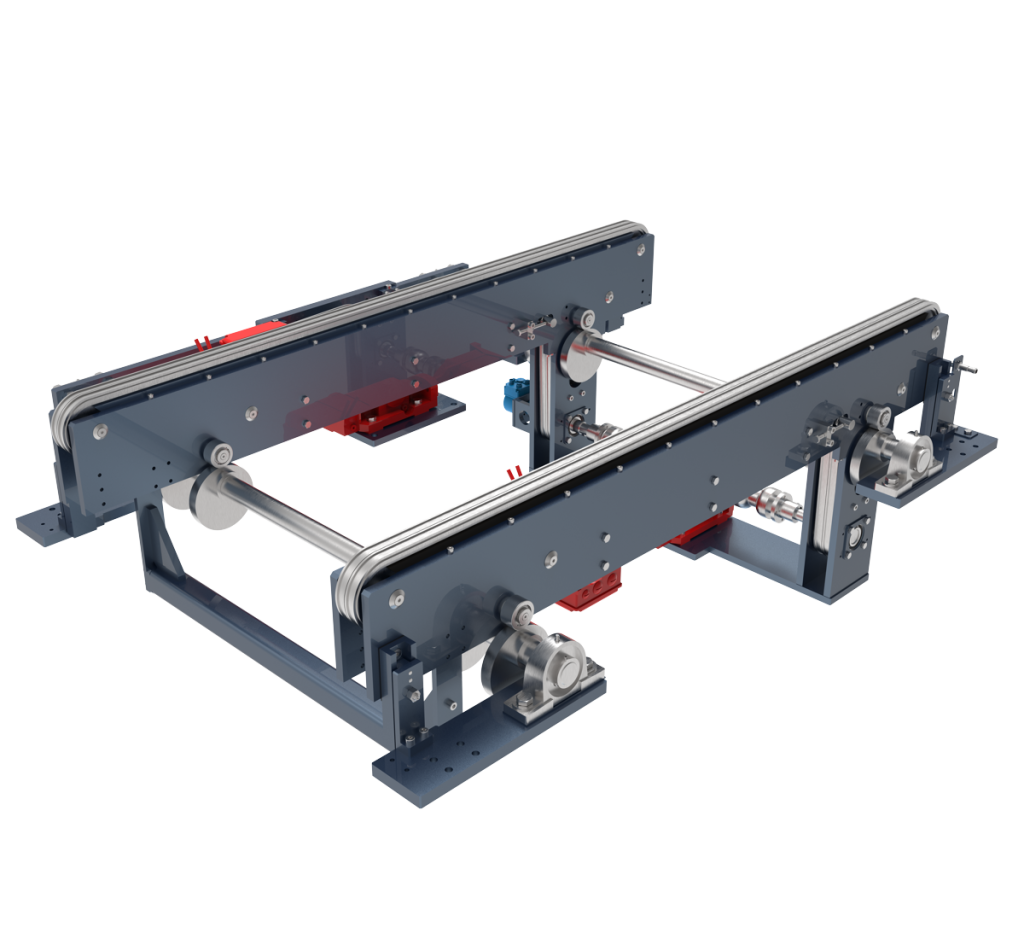

PHOEBUS X1

PHOEBUS X1 - Load capacity up to 50 Kg (110 Lbs). The PHOBUS is designed to back up the telescopic forks. The lateral belt conveyor allows moving the loads onboard simultaneously. The PHOEBUS can pick up the load from the shelf and lay it down in the unloading bay without needing a telescopic stroke.

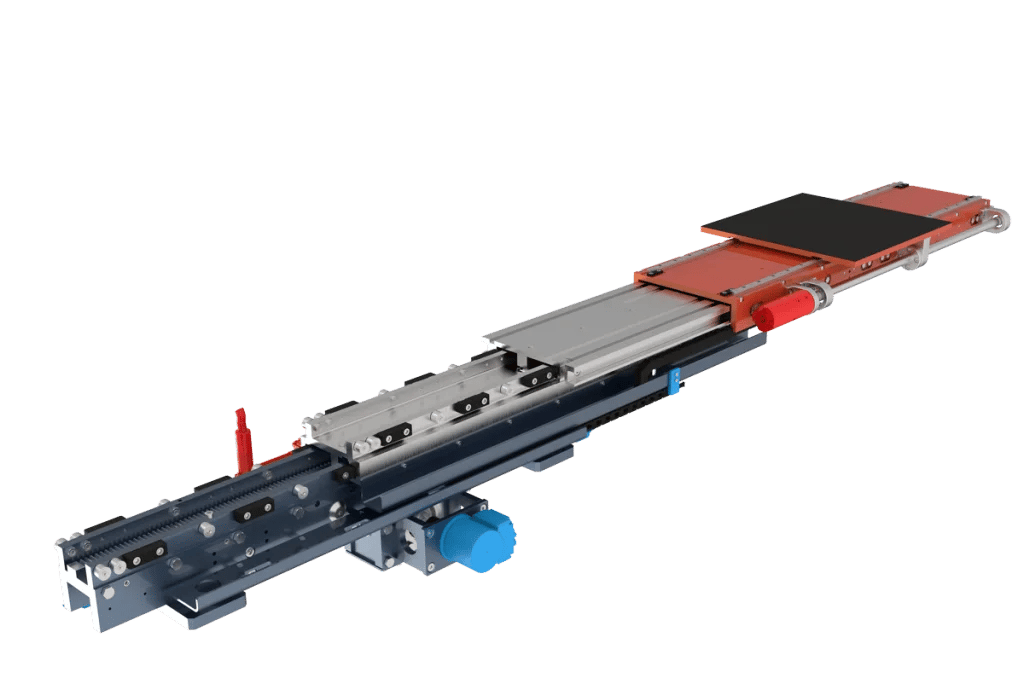

PHOEBUS X2

PHOEBUS X2 - Load capacity up to 100 Kg (220 Lbs). The PHOBUS X2 is designed to back up the telescopic forks. The lateral belt conveyor allows moving the loads onboard simultaneously. The PHOEBUS X2 can pick up the load from the shelf and lay it down in the unloading bay without needing the assistance of a telescopic stroke. The number of belts can be redoubled, thus making it even more flexible and versatile – it can also handle a double load onboard. Therefore, halving the operation time is possible by handling two loads simultaneously. The same system can involve chains instead of belts to handle much larger loads.

SPHINX

SPHINX - Load capacity up to 1500 kg (3307 Lbs). The SPHINX is a mobile carriage that can be attached to the vertical mast of forklift trucks. It enables the forklift to function as a stacker crane on wheels. With this attachment, the forklift can move pallets laterally in a warehouse, allowing it to operate in narrower aisles.

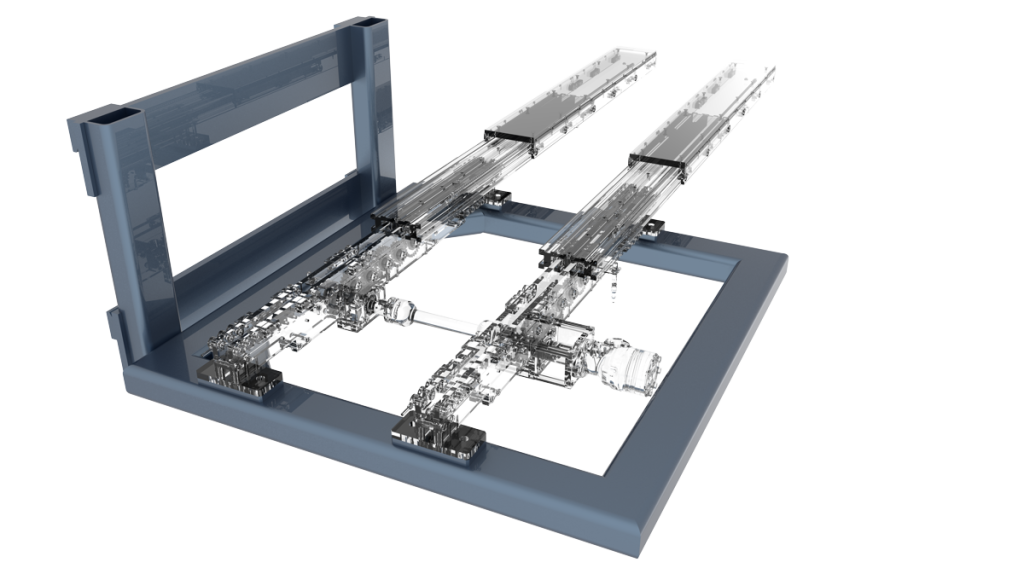

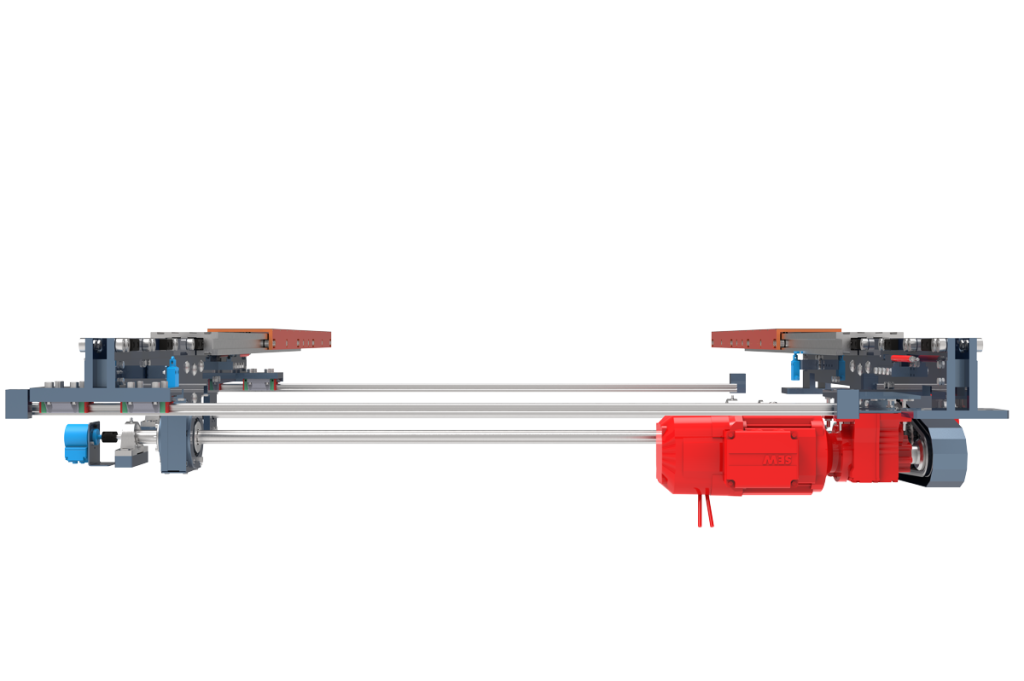

VARIAXIS

VARIAXIS – Load capacity up to 2000 Kg (4400 Lbs.) In modern automated warehouses, there is a need to reduce production time by handling different types and sizes of loads simultaneously. Typically, fork sets have a fixed inter-axis and can only handle specific loads. However, LHD has devised a solution to this issue by installing an adjustable inter-axis system under the fork set. This system makes the stocking operation more flexible and versatile. A motor operates a system of screws with recirculating balls and prismatic rails, which allows for the shifting of one or both forks symmetrically. The Integration of this adjustable inter-axis system into the fork system must be done before installation. The shift movement of adjusting the inter-axis is very quick and it`s programmable. The VARIAXIS system can be applied to all LHD telescopic forks, including those designed for coil handling.

Contact an LHD- USA (CDWdrives) engineer to discuss and customize your load-handling solution.